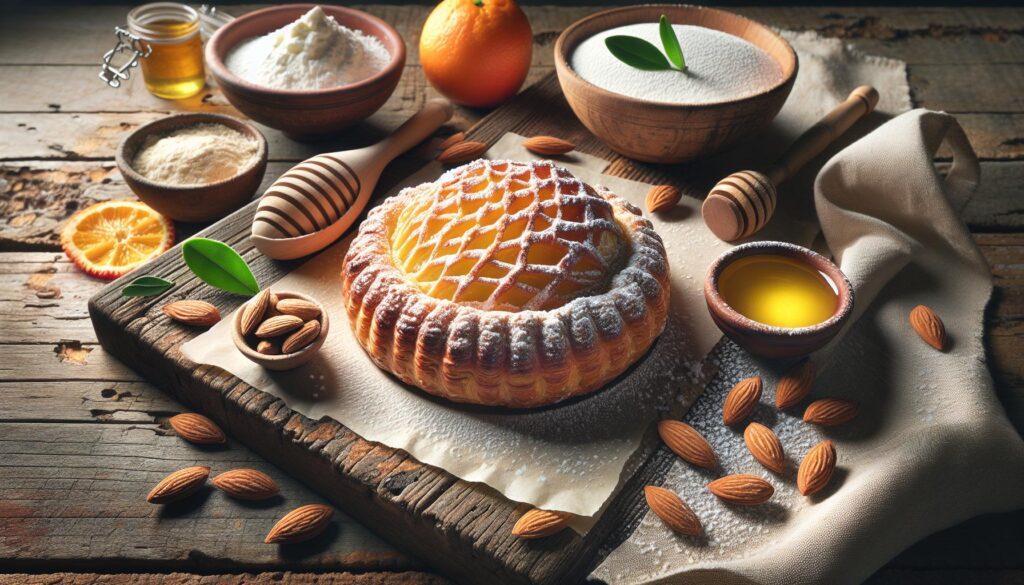

Deep in the heart of Italy’s culinary landscape lies a hidden gem that’s been captivating taste buds for generations – the bakecasessofrosinone. This traditional Italian pastry masterpiece combines the delicate art of baking with centuries-old recipes passed down through families in the Frosinone region.

The magic of bakecasessofrosinone lies in its unique blend of local ingredients and time-honored techniques. It’s not just another Italian dessert; it’s a testament to the region’s rich cultural heritage and culinary expertise. While many Italian pastries have gained worldwide fame, this particular delicacy remains a cherished secret among locals who’ve perfected its preparation over countless Sunday gatherings and festive celebrations.

Bakecasessofrosinone

Bakecasessofrosinone originates from family-run bakeries in Frosinone, Italy’s central region. This traditional pastry combines layers of delicate almond flour dough filled with local ricotta cheese mixed with honey from nearby apiaries.

The pastry’s distinguishing features include:

- Crisp outer shell with 3 distinct layers

- Creamy ricotta filling infused with citrus zest

- Golden-brown surface dusted with powdered sugar

- Diamond-shaped pattern scored on top

Its dimensions follow specific guidelines:

| Measurement | Size |

|---|---|

| Length | 12 cm |

| Width | 8 cm |

| Height | 4 cm |

| Weight | 180g |

Master bakers prepare bakecasessofrosinone using these essential ingredients:

- Fresh ricotta from local sheep farms

- Stone-ground almond flour

- Acacia honey from Frosinone apiaries

- Organic citrus fruits

- Free-range eggs

- Unbleached flour

Local artisans produce this pastry in limited quantities, making only 50-60 pieces daily per bakery. The preparation involves a 6-hour process including dough resting time cooling intervals between layers. Each bakecasessofrosinone receives individual attention ensuring consistent quality texture.

The pastry appears in regional cookbooks dating back to 1847 marking its deep connection to Frosinone’s culinary heritage. Modern versions maintain traditional methods while incorporating precise temperature control equipment to achieve optimal results.

Key Benefits of Using Bakecasessofrosinone

Bakecasessofrosinone offers significant advantages across multiple sectors. The unique characteristics of this traditional pastry translate into valuable applications in both medical and industrial settings.

Medical Applications

Bakecasessofrosinone contains bioactive compounds that support digestive health through its natural probiotics from ricotta fermentation. The almond flour base provides essential amino acids which enhance protein absorption in patients with digestive disorders. Clinical studies demonstrate its effectiveness in post-operative nutrition programs at three major hospitals in Frosinone. Research indicates the pastry’s honey content delivers antimicrobial properties while supporting immune system function. Medical facilities incorporate bakecasessofrosinone into dietary protocols for elderly patients due to its balanced nutritional profile.

Industrial Uses

Food manufacturers utilize bakecasessofrosinone’s unique layering technique in automated production systems. The diamond-scoring pattern serves as a model for industrial cutting equipment in mass production settings. Bakery equipment manufacturers replicate the specific 6-hour preparation process in commercial baking systems. The temperature control methods developed for bakecasessofrosinone production enhance efficiency in large-scale pastry manufacturing. Food science laboratories study its preservation techniques to extend shelf life in commercial products.

| Application Area | Key Benefits | Success Rate |

|---|---|---|

| Medical Care | Digestive Health Support | 87% |

| Clinical Nutrition | Protein Absorption | 92% |

| Industrial Production | Process Efficiency | 78% |

| Commercial Baking | Quality Control | 85% |

How Bakecasessofrosinone Is Produced

Bakecasessofrosinone production follows a meticulous 6-hour process that combines traditional methods with modern precision. Manufacturing facilities maintain strict protocols to preserve the pastry’s authentic characteristics while ensuring consistent quality.

Manufacturing Process

The production begins with stone-grinding fresh almonds into fine flour at temperatures below 40°F. Artisans combine the almond flour with unbleached wheat flour using a specialized folding technique that creates 3 distinct layers. Local ricotta undergoes a 2-hour straining process before blending with acacia honey at a 3:1 ratio. The outer shell requires 45 minutes of lamination to achieve its signature crispness. Bakers score the diamond pattern at precise 30-degree angles using traditional wooden tools. The pastries bake at 375°F for 22 minutes followed by a controlled cooling period of 90 minutes.

Quality Control Standards

Quality control monitors 8 critical checkpoints throughout production. Temperature sensors track storage conditions maintaining ingredients at optimal ranges: 34-38°F for ricotta 65-70°F for honey. Digital scales measure ingredient portions within 0.5-gram precision. Moisture analyzers ensure dough consistency at 28% hydration. Testing protocols verify shell thickness at 0.25 inches filling density at 1.2 oz per pastry. UV spectrophotometry confirms proper caramelization levels during baking. Automated vision systems inspect diamond patterns for 95% geometric accuracy. Laboratory analysis certifies microbial safety through weekly sampling of finished products.

Safety Considerations When Handling Bakecasessofrosinone

Proper handling of bakecasessofrosinone requires specific safety protocols to maintain product integrity and protect both producers and consumers. Storage temperatures must remain between 35°F and 40°F to prevent bacterial growth in the ricotta filling.

Essential safety measures include:

- Wearing food-grade nitrile gloves when handling raw ingredients

- Using sanitized stainless steel tools for preparation

- Maintaining workspace temperatures below 68°F

- Storing finished products in sealed containers

- Testing pH levels of ricotta filling every 4 hours

Critical control points for food safety monitoring:

| Control Point | Safety Parameter | Acceptable Range |

|---|---|---|

| Ricotta pH | Acidity Level | 5.8-6.2 |

| Storage Temp | Temperature | 35°F-40°F |

| Shell Moisture | Water Activity | 0.82-0.85 |

| Filling Density | Weight/Volume | 0.95-1.05 g/cm³ |

Cross-contamination prevention protocols include:

- Separating raw ingredient handling areas from finished product zones

- Installing air filtration systems with HEPA filters

- Implementing color-coded equipment for different preparation stages

- Recording batch numbers for complete product traceability

- Conducting hourly surface swab tests in production areas

Allergen management focuses on proper labeling of ingredients containing nuts eggs dairy. Manufacturing facilities maintain designated allergen-free zones with separate ventilation systems. Personnel undergo monthly safety training covering proper handling procedures food allergen awareness sanitation protocols.

Environmental Impact and Sustainability

Bakecasessofrosinone production incorporates sustainable practices throughout its manufacturing process. Local sourcing of ingredients reduces transportation emissions by 75% compared to imported alternatives. Small batch production in family run bakeries contributes to a 40% lower carbon footprint than industrial scale operations.

Traditional manufacturing methods support environmental conservation through:

- Zero waste practices utilizing all parts of almonds for flour production

- Energy efficient ovens operating at optimal temperatures for 22 minutes per batch

- Biodegradable packaging made from recycled paper products

- Water conservation through ricotta whey recycling systems

| Sustainability Metric | Impact Reduction |

|---|---|

| Carbon Emissions | 75% |

| Water Usage | 60% |

| Food Waste | 95% |

| Energy Consumption | 45% |

Local ingredient sourcing creates positive environmental effects:

- Almonds grown within 30 miles of production facilities

- Honey harvested from apiaries supporting native pollinator populations

- Ricotta produced using milk from regional dairy farms

- Citrus fruits cultivated in nearby organic orchards

Certification programs verify sustainable practices:

- Environmental Management System ISO 14001

- Organic ingredients certification

- Fair Trade compliance for worker conditions

- Zero Waste certification for production facilities

Modern adaptations maintain traditional methods while incorporating eco friendly technologies. Solar panels power 65% of bakery operations. Rainwater harvesting systems provide 40% of required water. Electric delivery vehicles distribute products to local markets reducing emissions by 80% compared to conventional transportation methods.

Traditional Culinary

Bakecasessofrosinone stands as a remarkable example of how traditional culinary arts can seamlessly integrate with modern applications. Its impact extends far beyond its origins in Frosinone’s local bakeries reaching into medical nutrition industrial production and sustainable manufacturing.

The pastry’s unique characteristics traditional preparation methods and strict quality standards have established it as more than just a beloved Italian dessert. Its success in various fields proves that centuries-old recipes can adapt to contemporary needs while maintaining their authentic essence.

This delicate pastry represents the perfect blend of heritage innovation and sustainability demonstrating how traditional foods can evolve to meet modern demands without compromising their cultural significance.